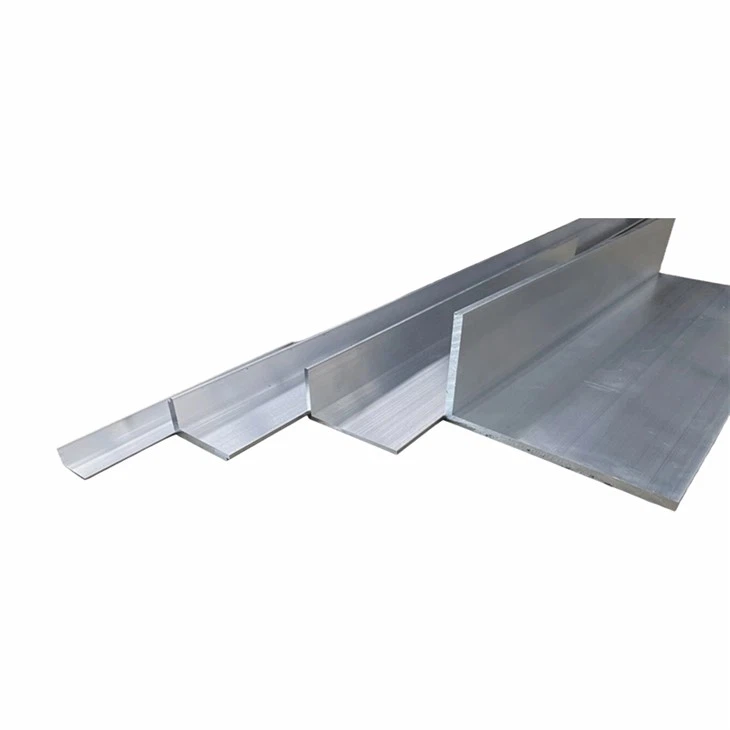

In the vast landscape of industrial machinery, L Type Angle Bars stand out as versatile and indispensable components. As a dedicated supplier of L Type Angle Bars, I have witnessed firsthand the diverse applications and the crucial role these bars play in various industrial settings. This blog post aims to explore the wide range of applications of L Type Angle Bars in industrial machinery, highlighting their unique properties and benefits.

Structural Support

One of the primary applications of L Type Angle Bars in industrial machinery is providing structural support. These bars are commonly used to reinforce frames, brackets, and other load - bearing components. Their L - shaped design offers excellent strength and stability, making them ideal for withstanding heavy loads and forces.

In machine frames, L Type Angle Bars are often used to connect different parts and provide rigidity. For example, in large - scale manufacturing equipment, the frame needs to be sturdy enough to support the weight of the machinery and any external forces during operation. By using L Type Angle Bars at the corners and joints of the frame, the overall structural integrity is significantly enhanced. The bars distribute the load evenly, reducing the risk of deformation or failure.

Moreover, in conveyor systems, L Type Angle Bars are used to support the conveyor belts and the associated components. They help maintain the alignment of the conveyor and prevent it from sagging or shifting under the weight of the transported materials. This ensures the smooth and efficient operation of the conveyor system, minimizing downtime and maintenance costs.

Bracing and Stabilization

L Type Angle Bars are also widely used for bracing and stabilization purposes in industrial machinery. In equipment that experiences vibrations or dynamic forces, such as engines and generators, these bars are used to prevent excessive movement and ensure the stability of the machine.

For instance, in a diesel engine, L Type Angle Bars can be used to brace the engine block to the mounting frame. This helps absorb the vibrations generated during the engine's operation and reduces the stress on the mounting points. By stabilizing the engine, the risk of damage to the engine and its surrounding components is reduced, and the overall lifespan of the engine is extended.

In addition, in robotic arms and other automated machinery, L Type Angle Bars are used to provide lateral support and prevent the arms from swaying or bending during movement. This is crucial for maintaining the accuracy and precision of the robotic operations, especially in applications where high - level precision is required, such as in the electronics manufacturing industry.

Fixturing and Alignment

Another important application of L Type Angle Bars in industrial machinery is fixturing and alignment. These bars are used to create precise fixtures and jigs that hold workpieces in place during machining, assembly, and inspection processes.

In a machining center, L Type Angle Bars can be used to create a fixture for holding a metal part during milling or drilling operations. The right - angled shape of the bars allows for easy alignment of the workpiece, ensuring that the machining operations are carried out accurately. This helps improve the quality of the machined parts and reduces the scrap rate.

During the assembly of complex machinery, L Type Angle Bars are used to align different components and ensure that they are properly positioned relative to each other. For example, in the assembly of a large - scale printing press, these bars can be used to align the printing cylinders, rollers, and other components, ensuring that the press operates smoothly and produces high - quality prints.

Protection and Safety

L Type Angle Bars also play a role in providing protection and safety in industrial machinery. They can be used to create guards and barriers that prevent operators from coming into contact with moving parts or hazardous areas of the machine.

In a woodworking machine, such as a table saw, L Type Angle Bars can be used to construct a safety guard around the saw blade. The bars provide a rigid structure for the guard, ensuring that it remains in place and effectively protects the operator from accidental contact with the blade.

In addition, in industrial equipment that operates in harsh environments, L Type Angle Bars can be used to protect the machine from physical damage. For example, in a mining machine, these bars can be used to reinforce the outer casing of the machine, protecting it from impacts and abrasions caused by rocks and other debris.

Customization and Adaptability

One of the advantages of using L Type Angle Bars in industrial machinery is their high degree of customization and adaptability. As a supplier, we offer a wide range of L Type Angle Bars in different materials, sizes, and thicknesses to meet the specific requirements of various industrial applications.

For applications that require high corrosion resistance, we offer Stainless Steel 304 Angle Bar. Stainless steel 304 is known for its excellent corrosion resistance, making it suitable for use in industries such as food processing, chemical manufacturing, and marine applications.

For more general - purpose applications, our Standard Angle Bar provides a cost - effective solution. These bars are made from high - quality carbon steel and offer good strength and durability.

If you are looking for a specific type of L Type Angle Bar, our L Type Angle Bar product page offers a comprehensive selection. We can also customize the bars according to your specific dimensions and requirements, ensuring that you get the perfect solution for your industrial machinery.

Conclusion

In conclusion, L Type Angle Bars are incredibly versatile components with a wide range of applications in industrial machinery. From providing structural support and bracing to fixturing and protection, these bars play a crucial role in ensuring the efficient, safe, and reliable operation of industrial equipment.

As a supplier of L Type Angle Bars, we are committed to providing high - quality products that meet the diverse needs of our customers. Whether you are in the manufacturing, mining, food processing, or any other industry, we have the right L Type Angle Bar solution for you.

If you are interested in learning more about our L Type Angle Bars or would like to discuss your specific requirements, please feel free to reach out to us. We look forward to the opportunity to work with you and contribute to the success of your industrial machinery projects.

References

- Machinery's Handbook, Industrial Press Inc.

- Handbook of Industrial Engineering, John Wiley & Sons, Inc.

- ASME Standards for Mechanical Engineering Design, American Society of Mechanical Engineers.