How to manufacture 410 stainless steel wire?

As a trusted supplier of 410 stainless steel wire, I am thrilled to share with you the intricate process of manufacturing this remarkable material. 410 stainless steel wire is renowned for its excellent corrosion resistance, high strength, and good formability, making it a popular choice in various industries such as automotive, aerospace, and construction.

Raw Material Selection

The journey of manufacturing 410 stainless steel wire begins with the careful selection of raw materials. The primary components of 410 stainless steel are iron, chromium, and carbon. Chromium is the key element that provides the steel with its corrosion-resistant properties, while carbon contributes to its strength and hardness.

We source high-quality raw materials from reputable suppliers to ensure the consistency and quality of our 410 stainless steel wire. The raw materials are carefully inspected and tested to meet the strictest industry standards before they are used in the manufacturing process.

Melting and Casting

Once the raw materials are selected, they are melted in an electric arc furnace. The furnace heats the materials to a temperature of around 1,600°C, causing them to melt and form a homogeneous liquid. During the melting process, various alloying elements may be added to the molten steel to achieve the desired chemical composition and properties.

After the steel is melted, it is cast into billets or ingots. The casting process involves pouring the molten steel into molds and allowing it to solidify. The billets or ingots are then cooled slowly to prevent the formation of cracks and other defects.

Hot Rolling

The next step in the manufacturing process is hot rolling. The billets or ingots are reheated to a temperature of around 1,200°C and then passed through a series of rolling mills. The rolling mills apply pressure to the steel, reducing its thickness and increasing its length. This process also helps to refine the grain structure of the steel, improving its mechanical properties.

Hot rolling is typically carried out in multiple passes, with the steel being gradually reduced in thickness with each pass. The final thickness of the steel depends on the specific requirements of the customer.

Cold Drawing

After hot rolling, the steel is subjected to cold drawing. Cold drawing is a process in which the steel is pulled through a series of dies, reducing its diameter and increasing its length. This process helps to further refine the grain structure of the steel, improving its strength and surface finish.

Cold drawing is typically carried out in multiple passes, with the steel being gradually reduced in diameter with each pass. The final diameter of the steel depends on the specific requirements of the customer.

Heat Treatment

Heat treatment is an important step in the manufacturing process of 410 stainless steel wire. Heat treatment involves heating the steel to a specific temperature and then cooling it at a controlled rate. This process helps to improve the mechanical properties of the steel, such as its strength, hardness, and toughness.

There are several different types of heat treatment that can be applied to 410 stainless steel wire, including annealing, quenching, and tempering. The specific heat treatment process used depends on the desired properties of the steel.

Surface Treatment

After heat treatment, the steel may be subjected to surface treatment to improve its corrosion resistance and appearance. Surface treatment options include pickling, passivation, and electroplating.

Pickling is a process in which the steel is immersed in an acid solution to remove any scale or oxide layers from its surface. Passivation is a process in which the steel is treated with a chemical solution to form a protective oxide layer on its surface. Electroplating is a process in which a thin layer of metal is deposited on the surface of the steel to improve its corrosion resistance and appearance.

Quality Control

Throughout the manufacturing process, strict quality control measures are implemented to ensure the consistency and quality of our 410 stainless steel wire. Our quality control team conducts regular inspections and tests on the raw materials, intermediate products, and finished products to ensure that they meet the strictest industry standards.

Some of the tests that we perform include chemical analysis, mechanical testing, and non-destructive testing. Chemical analysis is used to determine the chemical composition of the steel, while mechanical testing is used to evaluate its strength, hardness, and other mechanical properties. Non-destructive testing is used to detect any internal defects or flaws in the steel.

Packaging and Shipping

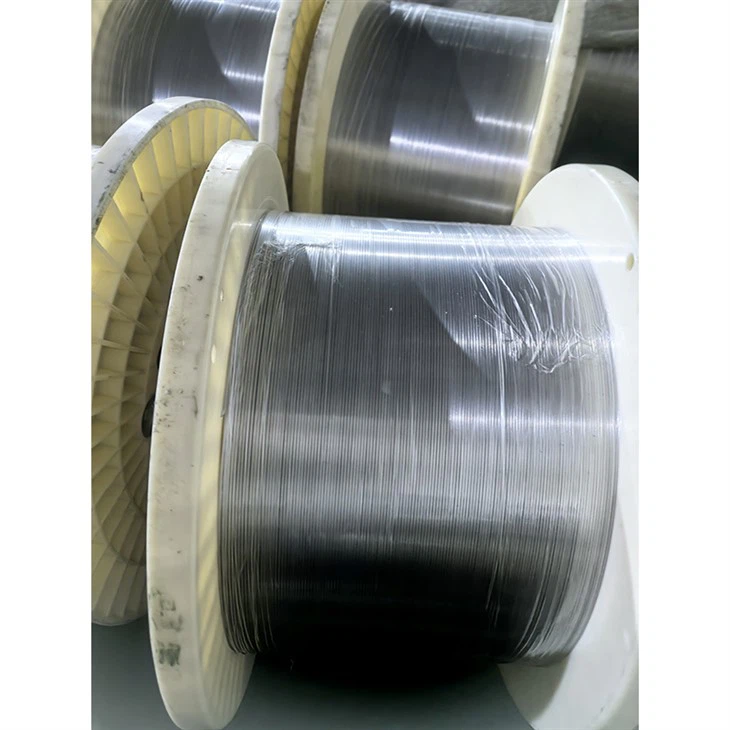

Once the 410 stainless steel wire is manufactured and tested, it is carefully packaged and shipped to our customers. We use high-quality packaging materials to ensure that the wire is protected during transportation and storage. The wire is typically packaged in coils or spools, depending on the specific requirements of the customer.

We offer a variety of shipping options to our customers, including air freight, sea freight, and land transportation. Our logistics team works closely with our customers to ensure that the wire is delivered to their doorstep in a timely and efficient manner.

Conclusion

In conclusion, the manufacturing process of 410 stainless steel wire is a complex and intricate process that involves several steps, from raw material selection to final packaging and shipping. At [Company Name], we are committed to providing our customers with high-quality 410 stainless steel wire that meets their specific requirements and expectations.

If you are interested in purchasing 410 stainless steel wire or have any questions about our products or services, please do not hesitate to contact us. Our sales team will be happy to assist you and provide you with more information.

In addition to 410 stainless steel wire, we also offer a wide range of other stainless steel products, including 304 Stainless Steel Wire, Stainless Flat Wire, and 304L Stainless Wire. These products are also manufactured using the same high-quality standards and processes as our 410 stainless steel wire, ensuring that they meet the strictest industry requirements.

Thank you for reading this blog post. I hope you found it informative and useful. If you have any comments or suggestions, please feel free to leave them below.

References

- ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International, 1990.

- Metals Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Pure Metals. ASM International, 1990.

- Stainless Steel: A Guide to Selection, Fabrication, and Applications. ASM International, 1994.